The other day I got a very good deal on an RE-101 Space Echo and an Ampeg B-15N, both needing work. The Space Echo fixed right up--it just had some pots and switch contacts that needed cleaning and lubricating. So that was a win.

The B-15N was even more of a mess than I expected though, so it all evened out. This is a work in progress (I'm linking to pics hosted on a social media site, so hopefully they don't disappear).

As it arrived. I'm not a B-15 expert yet, but I think this is either a single baffle cab thats been highly worked over or someone's homemade reproduction that fits the original chassis tray. All logos missing, no ports on baffle (hinting that it's a replacement), covering looks like Fender Blond-era Nubtex that's been painted black with brush-on enamel.

There's a hole inside the cabinet; you can see a substantial amount of daylight through the bottom left corner.

Most hardware is either damaged or missing, with a mashup of cross-threaded incorrect screws of various sizes and thread pitches holding on what remains. An incorrect-looking metal plate holds a quarter-inch jack on the left side.

Nice Eminence Delta 15 speaker installed, though--a very good B-15 speaker that's not worlds apart from the original CTS sonically (a bit more low-end extension, perhaps).

A repro double-baffle cab from Fliptops is the way; this one looks destined either for "free local pickup" or the trash.

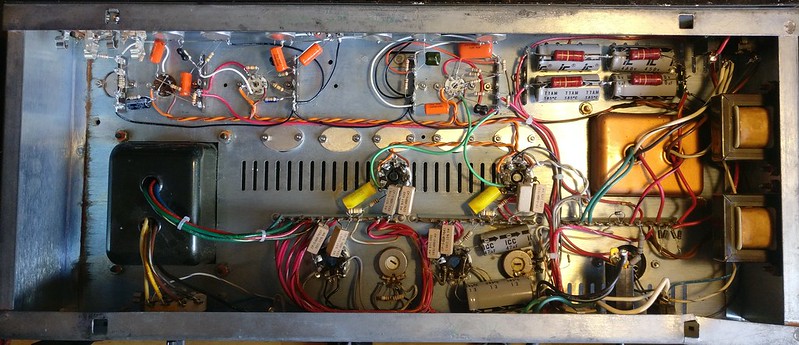

Inside is worse than I'd hoped. It's hard to parse what's even going on here--a real nightmare of amateurish work and sloppy bodge jobs. The first filter cap is literally electrical-taped to the wall of the chassis.

Underneath all of that, it looks like a mashup of parts from various eras.

It has the fixed-bias circuit, as the single-baffle cab would imply. But it's built out on an earlier-style eyelet board, with solder-lug tube sockets that are clearly original and riveted to the chassis in correct fashion. Chassis side pieces are plywood, which only happened before '64... so a lot of things don't really line up here.

Later-style PCB sub-assemblies hold the front panel controls... but the pots themselves are from the mid-1970s (a mix of Clarostat and CTS parts... most of the latter with incorrect splined shafts and solder lugs; clearly not factory).

The original 2-prong power cable remains; the speaker cable has been terminated with a quarter-inch connector (should be 4-pin XLR or octal)

Ground polarity switch is black instead of nickel. My working theory is that someone had two B-15s, took the best parts from each (in their estimation), and left the rest for dead... either got it barely-working, or left it to get trash-picked in the 70s or 80s by someone with DIY aspirations